Retrofit Okuma CNCs and Lathes with

Constant Governed 25,000 to 90,000 RPM and Torque

Air Turbine Tools® and Okuma America Corporation have partnered to deliver patented high-speed machining technology to Okuma CNC machines and lathes.

Through this partnership, Okuma users can integrate Air Turbine Spindles®, Air Turbine Live Tools®, and Air Turbine Motors® seamlessly into their machines, enabling constant high speed milling at governed speeds of 25,000–90,000 RPM with high power and 2 micron accuracy.

Watch 330% cycle time reduction on the Okuma Genos MB-46

Turn Your Okuma Into a High-Speed Powerhouse With Air Turbine Tools®

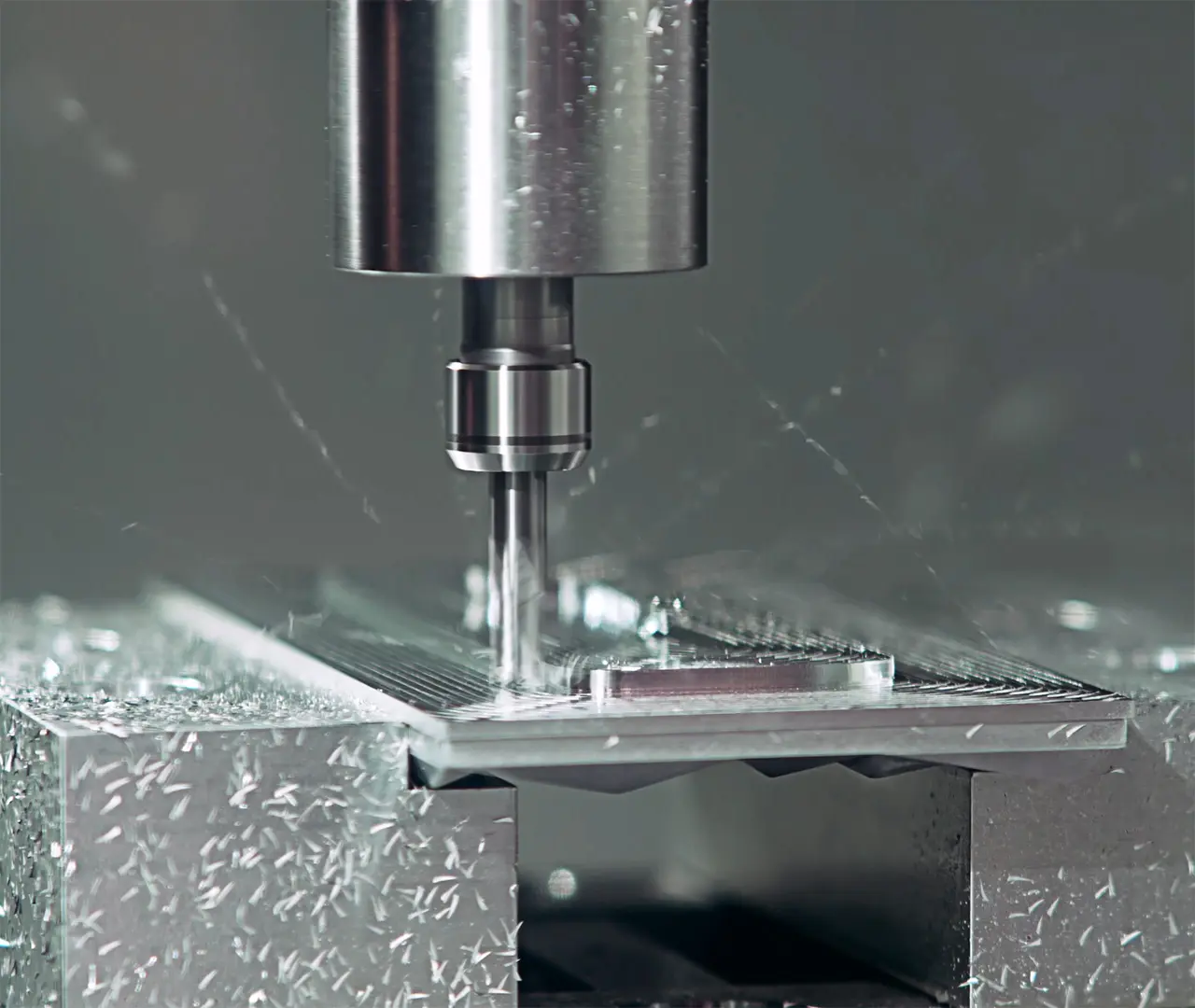

In this video, Air Turbine Spindles® in the Okuma Genos MB-46 reduced production time from 1 hour and 5 minutes down to just 15 minutes — a 330% cycle time reduction.

Automatic Tool Change On Okuma Genos CNC Machine

3 Simple Integration Options To Retrofit Your Okuma CNC Machine

You can upgrade your Okuma CNC for high-speed performance in minutes. Air Turbine Spindles® install easily and operate with no external electrical control systems. Powered by standard 90 psi clean, dry air supply, these oil-free spindles support automatic tool change, loading and unloading in the Okuma tool changer just like any standard tool.

Installation Options:

- Through-Spindle Air Connection

- Tool Changer Mounting Assembly (TMA)

- Manual Airline Connection

Maximize Okuma Spindle Life and Performance

Whether you’re producing for medical, aerospace or defense industries, all Okuma users can benefit from a solution that combines roughing and fine finishing in a single setup. Manufacturers working with small-tool will gain significant increases in their Okuma spindle life extending machine longevity.

“When paired with Air Turbine Tools® high-speed technology, the cycle time and wear on Okuma spindles are greatly reduced.”

Made in the USA and refined over 30 years of innovation, Air Turbine Tools® increases productivity for Okuma users globally.

Downloadable PDF Content

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].