INDEX

►

►

►

►

►

►

►

►

Read all instructions thoroughly before installation and use.

Downloadable PDF Content

User Notes and Setup

Accessory Part Numbers

Initial Installation

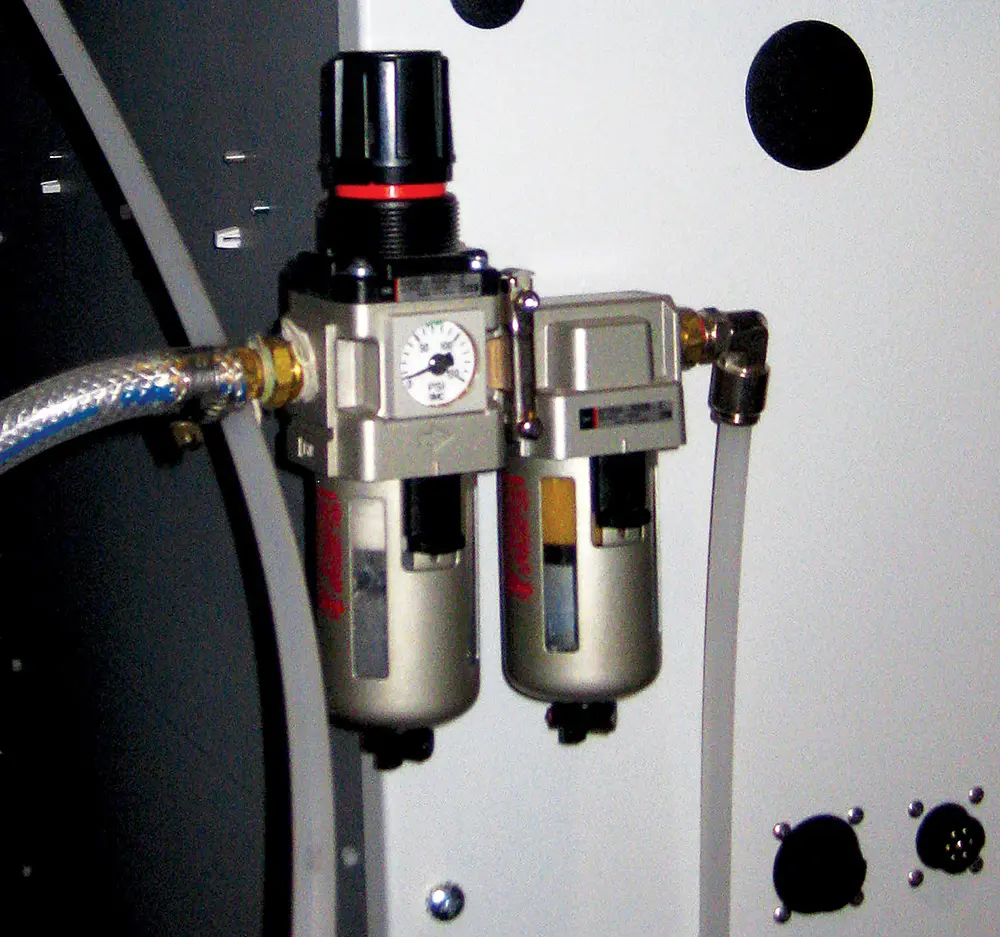

Install a new dedicated clean air line from a filter/regulator to your Air Turbine Motor® as shown in figure 1. filter/regulators are included with the 700 series of Air Turbine Motors®. Filter/regulators are available for an additional purchase.

Ensure all air lines and fittings meet the minimum internal diameter specified for your model as specified in figure 3. Additionally, place a plug in any air inlet that is not being used.

If working in a wet environment with the Sealed Steel series of Air Turbine Motors® install exhaust hoses as shown in figure 1. Internal diameters of exhaust hoses must be no smaller than the specified minimum required ID for your model as shown in figure 3.

Connection to air supply starts motor rotation. Do not connect air to your tool until installation is complete.

Optional: If you have a manual shut-off valve, install it after the filter/ regulator as shown in figure 2. Using a manual valve is recommended.

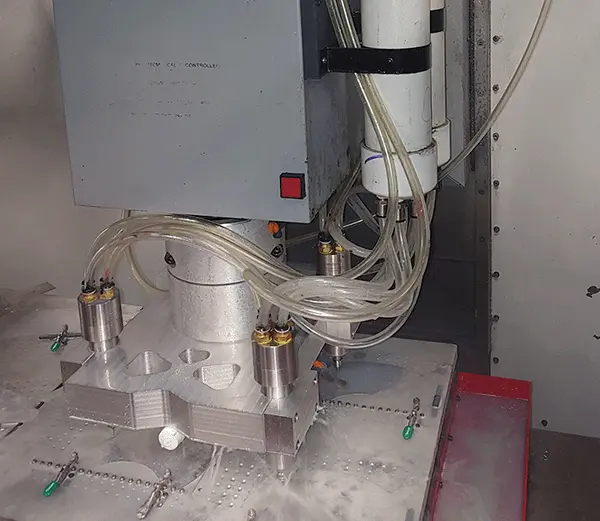

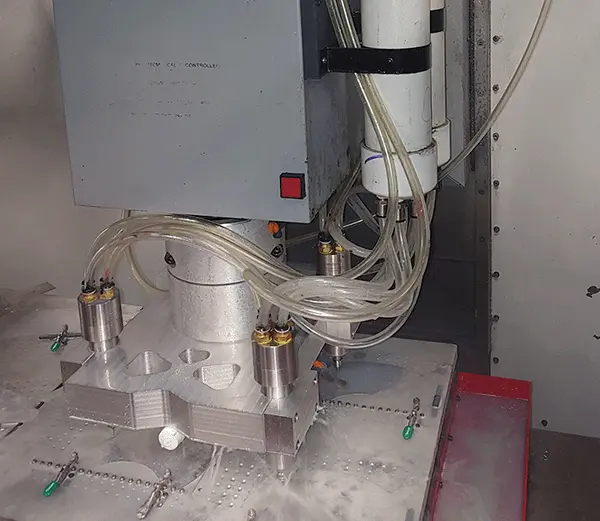

Figure 1: A clean airline from a filter/regulator to a mounted Air Turbine Motor® with exhaust hoses installed.

Figure 2: A clean airline from a filter/regulator to a mounted Air Turbine Motor® with manual shut-off valve installed.

Air Hoses and Fittings Requirements

Avoid fittings, couplings and hoses with a smaller internal diameter than the minimum required for your model. Any connections smaller than the minimum will restrict air flow and reduce power to your Air Turbine Motor®. You can find the minimum required internal diameter (ID) for fittings and hoses for your tool on the table shown in figure 3.

Air flow restrictions (such as air leaks and obstructions) will cause underpower performance and drag your tool through the material, damaging the bearings. Some fittings with nominal internal dimensions may have an ID passage that is smaller than stated and restrict air flow and power. It only takes one fitting with an internal diameter that is too small to reduce air flow and power of your Air Turbine Motor®.

| Air Hoses and Fittings Requirements for Air Turbine Motors® | ||

| Model | Hose/Connector Minimum Required Internal Diameter | |

| Metric | Imperial | |

| 5 mm | 0.1969” |

| 6 mm | 15/64” |

| 8 mm | 5/16” |

| 10 mm | 25/64” |

| Air Hoses, Connections, Fittings Minimumn Internal Diameter Requirements for Air Turbine Motors® |

| Model |

|

|

|

|

| Hose/Connector Minimum Required Internal Diameter | |

| Metric | Imperial |

| 5 mm | 0.1969” |

| 6 mm | 15/64” |

| 8 mm | 5/16” |

| 10 mm | 25/64” |

Figure 3: Air Turbine Motors® hose/fitting/connector internal diameter specifications.

Air Requirements

Ensure there is sufficient volume of clean compressed air flow at 90 psi/6.2 bar with the specified air flow volume CFM (L/s) for your model as shown in figure 4 to maintain working air consumption. Depending on application, consider peak or stall capacity consumption.

Our governor increases air flow volume on demand to keep rotation at the high speed when your tool starts to cut. Air pressure and flow volume must therefore be available on demand and remain constant with no drop over time or when cutting.

Refer to figure 4 for the idle CFM (L/s) rating vs. working air consumption ratings for all models of Air Turbine Motors®.

Connection to air supply starts motor rotation. Do not connect air to your tool until installation is complete.

Do not oil or lubricate. Use dry, clean, oil free 90 psi (6.2 bar) air supply only.

Avoid pressure below 90 psi (6.2 bar), which causes the tool to be dragged through the material, causing rapid bearing wear and underpowered performance. Do not use more than 100 psi (6.9 bar) pressure which will burst the turbine power producer.

Air pressure and flow must remain constant with no drops under cutting load. Insufficient flow will cause the rotation of your tool to slow or stop suddenly, damaging the bearings. If a drop in psi (bar) occurs below 90 psi (6.2 bar), your compressor may not have enough CFM (L/s) to power the Air Turbine Motor® or there is a flow restriction in the air line.

Idle CFM/L/s Rating vs. Working Air Consumption Ratings

Air Turbine Motors® consume more air as the cutting load or the amount of material removed increases.

This is normal operation of our patented governor which maintains high speed on your tool path and makes Air Turbine Motors® efficient in air consumption.

| Air Turbine Motors® Idle and Working Air Consumption Ratings |

|||

| Model | Speed | Air Consumption Idle | Air Consumption Working Flow |

| 50,000 RPM | 4 CFM (1.89 L/s) | 6 CFM - 9 CFM (2.83 L/s - 4.24 L/s) |

| 65,000 RPM | |||

| 40,000 RPM | 5 CFM (2.36 L/s) | 7 CFM - 10 CFM (3.3 L/s - 4.72 L/s) |

| 50,000 RPM | 6 CFM (2.83 L/s) | ||

| 40,000 RPM | 5 CFM (2.36 L/s) | 7 CFM - 10 CFM (3.3 L/s - 4.72 L/s) |

| 50,000 RPM | 6 CFM (2.83 L/s) | ||

| 65,000 RPM | |||

| 30,000 RPM | 10 CFM (4.72 L/s) | 11 CFM - 20 CFM (5.19 L/s - 9.44 L/s) |

| 40,000 RPM | 13 CFM (6.14 L/s) | ||

| 50,000 RPM | 14 CFM (6.61 L/s) | ||

| 65,000 RPM | |||

| 30,000 RPM | 14 CFM (6.61 L/s) | 14 CFM - 35 CFM (6.61 L/s - 16.52 L/s) |

| 40,000 RPM | |||

| 25,000 RPM | 13 CFM (6.14 L/s) | 14 CFM - 35 CFM (6.61 L/s - 16.52 L/s) |

| 30,000 RPM | 14 CFM (6.61 L/s) | ||

| 40,000 RPM | |||

| 30,000 RPM | 16 CFM (7.55 L/s) | 17 CFM - 45 CFM (18.02 L/s - 21.2 L/s) |

| 40,000 RPM | 20 CFM (9.44 L/s) | ||

| 50,000 RPM | |||

| 25,000 RPM | 14 CFM (6.61 L/s) | 19 CFM - 40 CFM (8.97 L/s - 18.89 L/s) |

| 30,000 RPM | 20 CFM (9.44 L/s) | ||

| 40,000 RPM | 23 CFM (10.85 L/s) | ||

| 50,000 RPM | 20 CFM (9.44 L/s) | 20 CFM - 35 CFM (9.44 L/s - 16.52 L/s) |

| Air Turbine Motors® Idle and Working Air Consumption Ratings |

| Model |

|

|

|

|

|

|

|

|

|

| Speed | Air Consumption Idle | Air Consumption Working Flow |

| 50,000 RPM | 4 CFM (1.89 L/s) | 6 CFM - 9 CFM (2.83 L/s - 4.24 L/s) |

| 65,000 RPM | ||

| 40,000 RPM | 5 CFM (2.36 L/s) | 7 CFM - 10 CFM (3.3 L/s - 4.72 L/s) |

| 50,000 RPM | 6 CFM (2.83 L/s) | |

| 40,000 RPM | 5 CFM (2.36 L/s) | 7 CFM - 10 CFM (3.3 L/s - 4.72 L/s) |

| 50,000 RPM | 6 CFM (2.83 L/s) | |

| 65,000 RPM | ||

| 30,000 RPM | 10 CFM (4.72 L/s) | 11 CFM - 20 CFM (5.19 L/s - 9.44 L/s) |

| 40,000 RPM | 13 CFM (6.14 L/s) | |

| 50,000 RPM | 14 CFM (6.61 L/s) | |

| 65,000 RPM | ||

| 30,000 RPM | 14 CFM (6.61 L/s) | 14 CFM - 35 CFM (6.61 L/s - 16.52 L/s) |

| 40,000 RPM | ||

| 25,000 RPM | 13 CFM (6.14 L/s) | 14 CFM - 35 CFM (6.61 L/s - 16.52 L/s) |

| 30,000 RPM | 14 CFM (6.61 L/s) | |

| 40,000 RPM | ||

| 30,000 RPM | 16 CFM (7.55 L/s) | 17 CFM - 45 CFM (18.02 L/s - 21.2 L/s) |

| 40,000 RPM | 20 CFM (9.44 L/s) | |

| 50,000 RPM | ||

| 25,000 RPM | 14 CFM (6.61 L/s) | 19 CFM - 40 CFM (8.97 L/s - 18.89 L/s) |

| 30,000 RPM | 20 CFM (9.44 L/s) | |

| 40,000 RPM | 23 CFM (10.85 L/s) | |

| 50,000 RPM | 20 CFM (9.44 L/s) | 20 CFM - 35 CFM (9.44 L/s - 16.52 L/s) |

Figure 4: Idle CFM (L/s) and working air consumption ratings for Air Turbine Motors®.

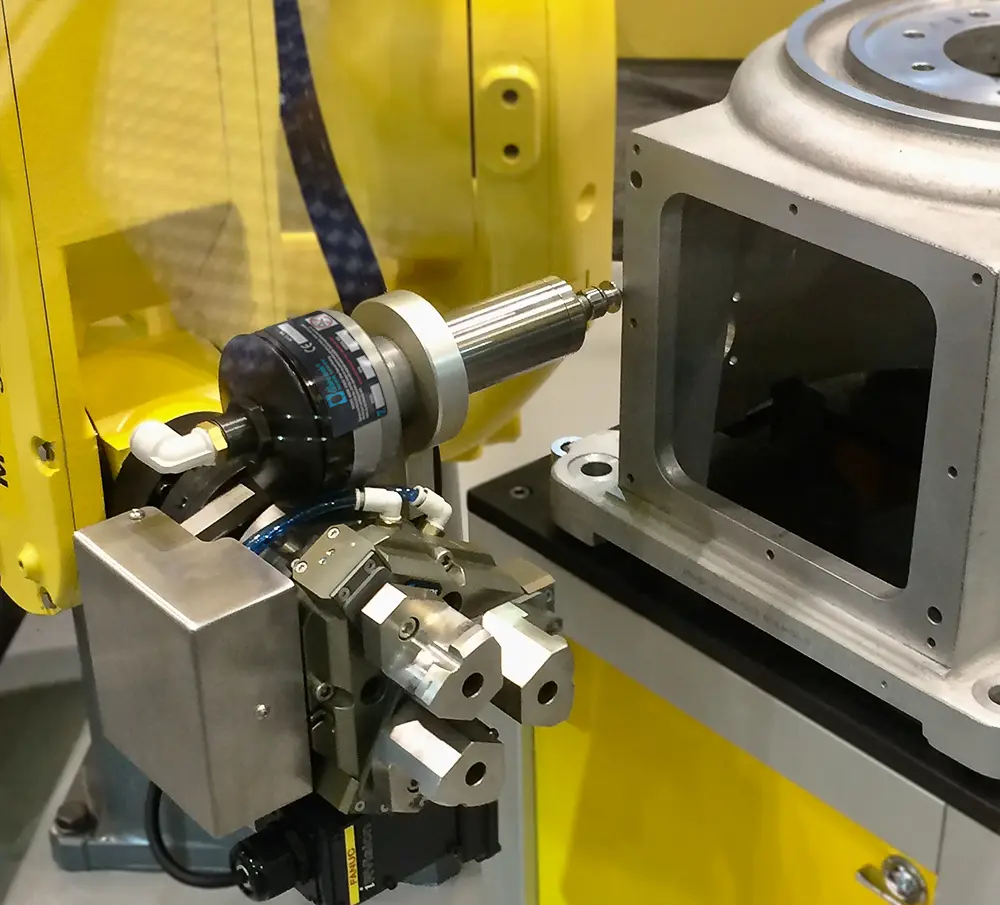

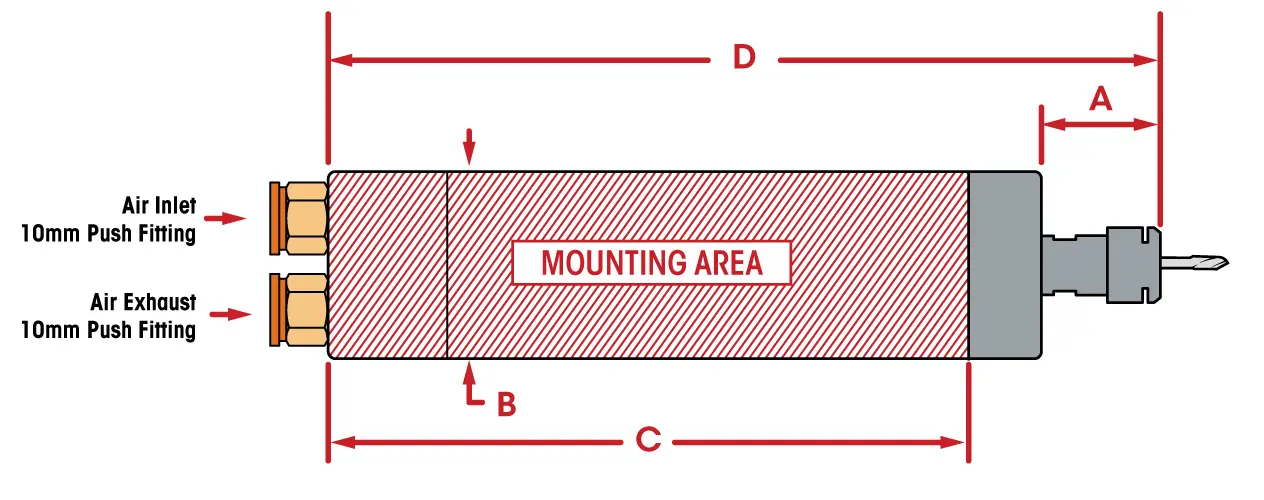

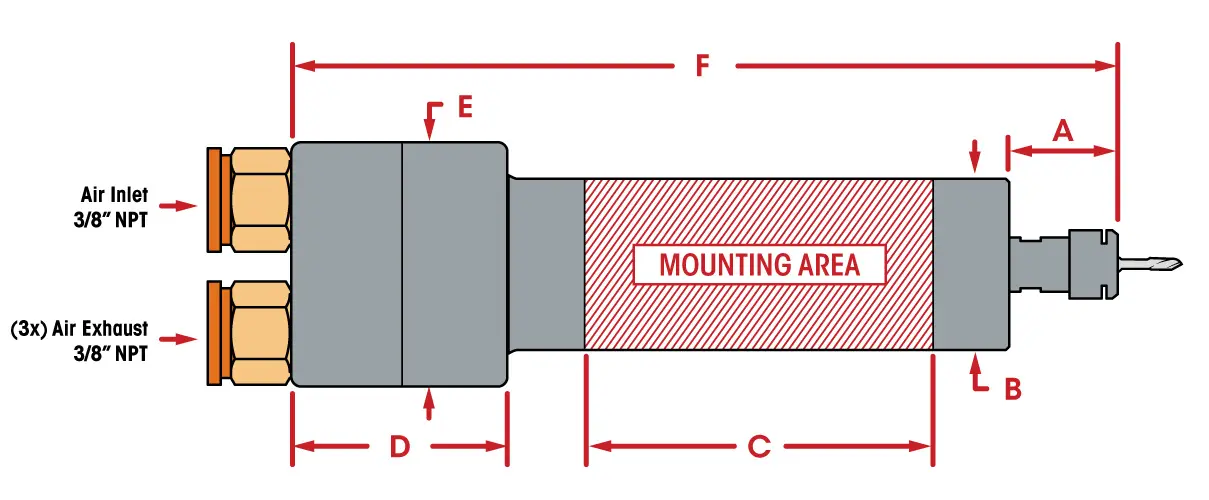

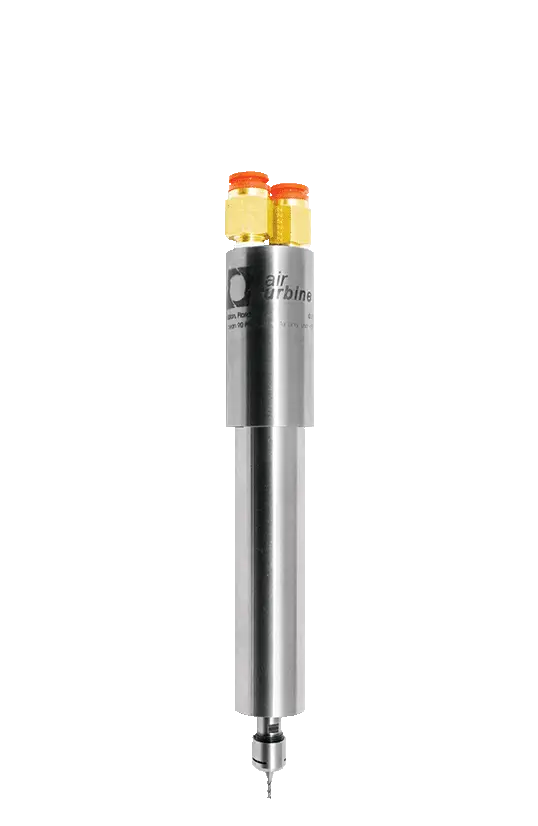

Mounting Air Turbine Motors® into your Lathe or Robot

When mounting your Air Turbine Motor®, make sure the fixture is only clamped on the labeled mounting area along the steel barrel for your model, as shown in figure 5 and in your model’s specifications sheet.

Incorrect positioning or over tightening of the clamp on your Air Turbine Motor® will result in pressure on the bearings and distorting the race. This will cause your motor to fail prematurely and will require a repair.

202HD Dimensional Drawing

Learn More About The 202HD

Learn More About The 202HD

| 202HD Dimensions | |||||

| A | 1.33” (33.84 mm) | D | 2.0” (50.8 mm) | F | Ø 2.0” (50.8 mm) |

| B | Ø 0.74” (18.84 mm) | ||||

| E | 5.35” (135.95 mm) | G | 7.13” (181.1 mm) | ||

| C | 4.27” (108.33 mm) | ||||

| 202HD Dimensions | |

| A | 1.33” (33.84 mm) |

| B | Ø 0.74” (18.84 mm) |

| C | 4.27” (108.33 mm) |

| D | 2.0” (50.8 mm) |

| E | 5.35” (135.95 mm) |

| F | Ø 2.0” (50.8 mm) |

| G | 7.13” (181.1 mm) |

450HD Dimensional Drawing

Learn More About The 450HD

Learn More About The 450HD

| 450HD Dimensions | |||||

| A | 1.05” (26.54 mm) | D | 2.5” (63.5 mm) | F | Ø 3.1” (79.74 mm) |

| B | Ø 1.62” (41.14 mm) | ||||

| E | 6.03” (153.16 mm) | G | 7.61” (193.29 mm) | ||

| C | 5.2” (132.08 mm) | ||||

| 450HD Dimensions | |

| A | 1.05” (26.54 mm) |

| B | Ø 1.62” (41.14 mm) |

| C | 5.2” (132.08 mm) |

| D | 2.5” (63.5 mm) |

| E | 6.03” (153.16 mm) |

| F | Ø 3.1” (79.74 mm) |

| G | 7.61” (193.29 mm) |

720MX Dimensional Drawing

Learn More About The 720MX

Learn More About The 720MX

| 720MX Dimensions | |||||

| A | 0.82” (20.83 mm) | C | 3.94” (100.08 mm) | E | Ø 1.18” (30 mm) |

| B | Ø 0.79” (20 mm) | D | 3.31” (84.07 mm) | F | 7.07” (179.58 mm) |

| 720MX Dimensions | |

| A | 0.82” (20.83 mm) |

| B | Ø 0.79” (20 mm) |

| C | 3.94” (100.08 mm) |

| D | 3.31” (84.07 mm) |

| E | Ø 1.18” (30 mm) |

| F | 7.07” (179.58 mm) |

722MX Dimensional Drawing

Learn More About The 722MX

Learn More About The 722MX

| 722MX Dimensions | |||||

| A | 0.82” (20.83 mm) | C | 3.94” (100.08 mm) | E | Ø 1.18” (30 mm) |

| B | Ø 0.87 (22 mm) | D | 3.31” (84.07 mm) | F | 7.07” (179.58 mm) |

| 722MX Dimensions | |

| A | 0.82” (20.83 mm) |

| B | Ø 0.87 (22 mm) |

| C | 3.94” (100.08 mm) |

| D | 3.31” (84.07 mm) |

| E | Ø 1.18” (30 mm) |

| F | 7.07” (179.58 mm) |

740MX Dimensional Drawing

Learn More About The 740MX

Learn More About The 740MX

| 740MX Dimensions | |||

| A | 1.0” (25.4 mm) | C | 5.25” (133.35 mm) |

| B | Ø 1.57 (40 mm) | D | 7.0” (177.8 mm) |

| 740MX Dimensions | |

| A | 1.0” (25.4 mm) |

| B | Ø 1.57 (40 mm) |

| C | 5.25” (133.35 mm) |

| D | 7.0” (177.8 mm) |

740XP Dimensional Drawing

Learn More About The 740XP

Learn More About The 740XP

| 740XP Dimensions | |||||

| A | 1.09” (27.69 mm) | C | 3.21” (81.52 mm) | E | Ø 2.25” (57.12 mm) |

| B | Ø 1.57” (40 mm) | D | 1.99” (50.51 mm) | F | 7.69” (195.33 mm) |

| 740XP Dimensions | |

| A | 1.09” (27.69mm) |

| B | Ø 1.57” (40.00mm) |

| C | 3.21” (81.52mm) |

| D | 1.99” (50.51mm) |

| E | Ø 2.25” (57.12mm) |

| F | 7.69” (195.33mm) |

202HD

450HD

720MX

722MX

740MX

740XP

Figure 5: Tables that show the proper mounting area and dimensions for mounting all Air Turbine Motors®.

Maintenance

Your Air Turbine Motor® must be run at least 10 minutes every 30 days from manufacture date to maintain optimal performance. Run at least 10 minutes before initial use.

The airline must be impeccably clean with no coupling or hose smaller than the minimum internal diameter required for your model as described in figure 3 so that air flow volume is unrestricted.

Purge the airline of contamination before each use.

When installing your cutting tool and collet, never hit the collet nut with the wrench.

A 0.3 micron filter extractor regulator combination is a necessary accessory for Air Turbine Motors® to eliminate impurities in your air supply. Contamination will damage your turbine components and require repair.

Filters are included with the Sealed Steel Series of Air Turbine Motors® and are required for all Air Turbine Motor® models. Filter elements need to be changed periodically and extractor drained in regular maintenance cycles.

Operation

Purge the line of contamination and run at least 10 minutes before initial use to ensure the bearing lubrication does not solidify.

Always monitor the air pressure gauge during operation of your Air Turbine Motor®. The key to successful high-speed machining and optimized tool performance is to program light passes at very high feed rates. Start with a light pass observing surface finish quality and gradually step down or increase your rate of advance for optimal cutting conditions.

Do not try to cut too aggressively. You will overload your turbine causing your cutting tool to stall or drag in the material. Dragging your tool on the work or a sudden stop will cause stress to the bearings and force the grease out, causing premature failure.

Certain rubber drilling applications require that the material goes through a cooling process after extrusion. This prevents heat from transferring from the material to the cutting tool and the bearings. This cooling process will reduce the risk of premature failure.

Working in a Wet Environment

The Sealed Steel series of Air Turbine Motors® are sealed for wet environments. In a wet environment, turn on the air supply to your Air Turbine Motor® before you turn on the coolant flow. At the end of the cycle turn the coolant off first. Only after the coolant flow is off, then you can turn off the air flow to your tool.

Learn More About Air Turbine Motors®

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].