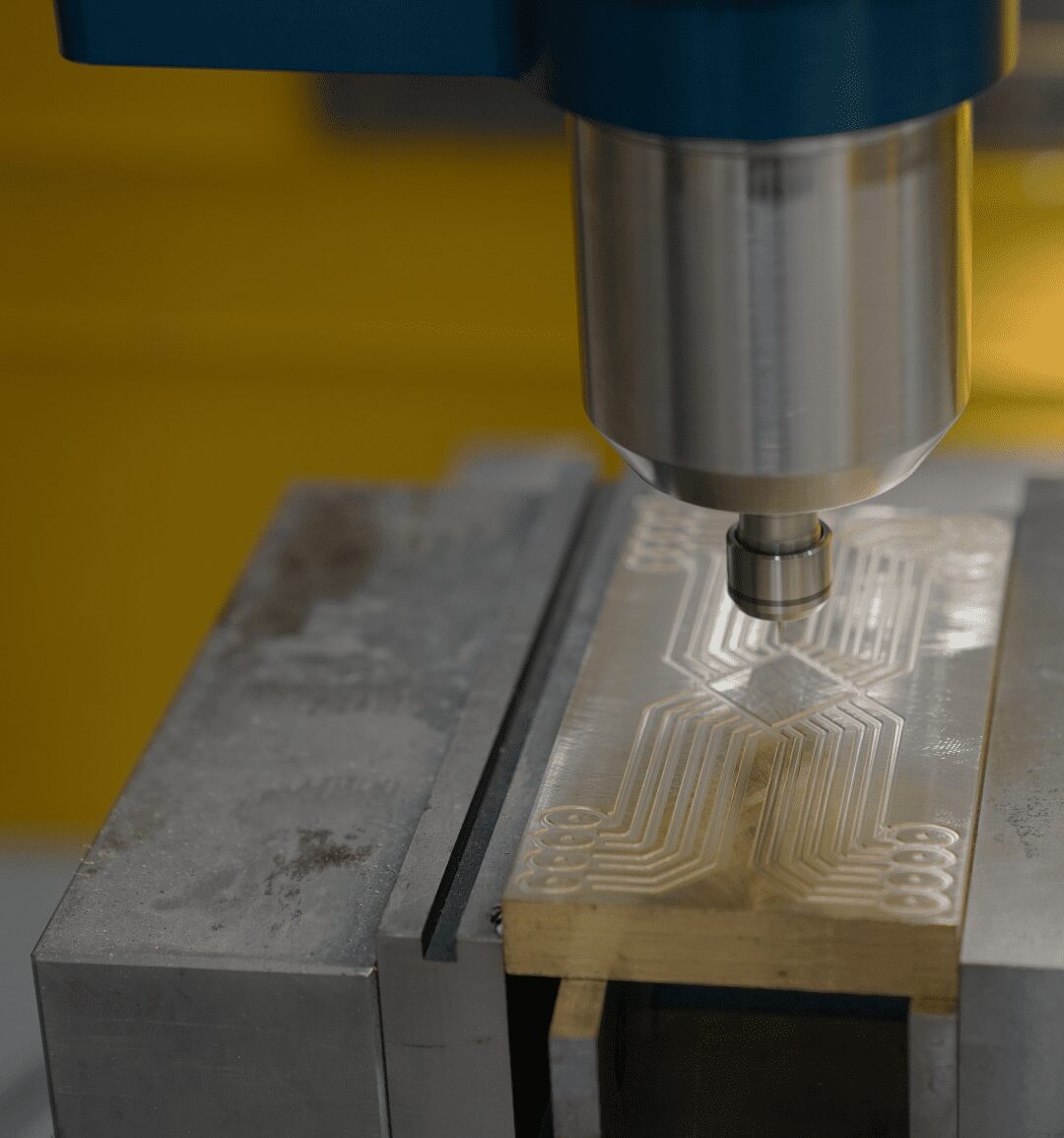

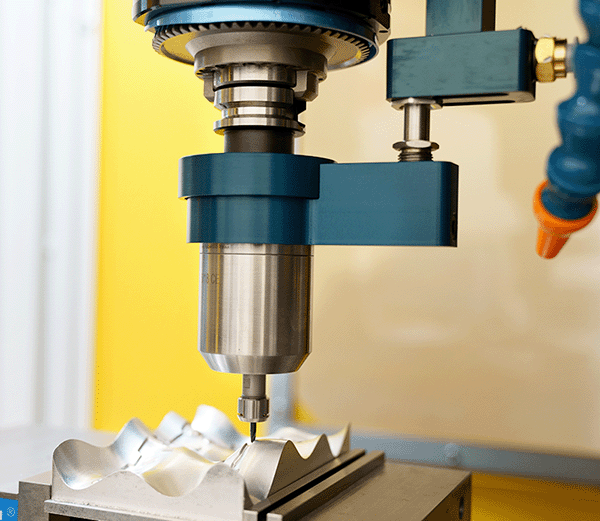

This New CNC Spindle Mills Molds at 80,000 RPM on Robodrill

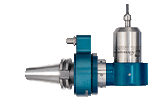

Retrofit your Robodrill

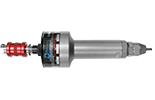

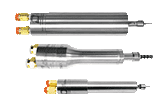

The powerful, totally oil-free low friction motor produces extremely low vibration and heat in continuous 24/7 operation. This unique patented direct drive has no vanes, gears or brushes to wear, burn or break.

Dramatically reduce your cycle times, optimize cutting tool performance and life. Air Turbine Spindles® use the highest quality runout and balancing systems on the market today. This creates the best dynamic runout accuracy and governed high speed precision.

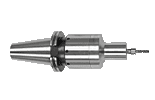

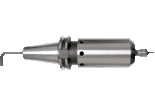

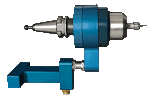

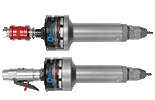

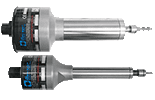

Autochange on FANUC Robodrill with Air Turbine Spindles® 625XDT and 602DT

No Need for Operator Downtime

with Autochange Functionality

Fully automated loading with our patented Toolchanger for 602DT & 625XDT on FANUC Robodrill get extra power for larger tools/drilling.

No oil required, and maintenance-free.

Videos

C/T Reduced by 25 Minutes with 50,000 rpm! Pocketing Brass with Air Turbine Spindles®

Aluminum Milling at 1000"/min - High Speed Spindles with No Duty Cycle

Milling Carbon Steel at 10,000 mm/min on Fanuc RoboDrill by Air Turbine Spindles® 50,000 rpm 625XDT

Aluminum Peck Drilling at 10"/min on Fanuc RoboDrill by Air Turbine Spindles® 50,000 rpm, 0.90 hp 625XDT

Cycle Times Cut Dramatically! Drilling Aluminum at 50,000 rpm on Robodrill

Pocketing Aluminum with 50,000 RPM on a Fanuc Robodrill with the Air Turbine Spindles® DT Series

Milling Plastic at 7000 mm/min on FANUC Robodrill by Air Turbine Spindles® 50,000 rpm, 0.76 hp 625XDT

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].