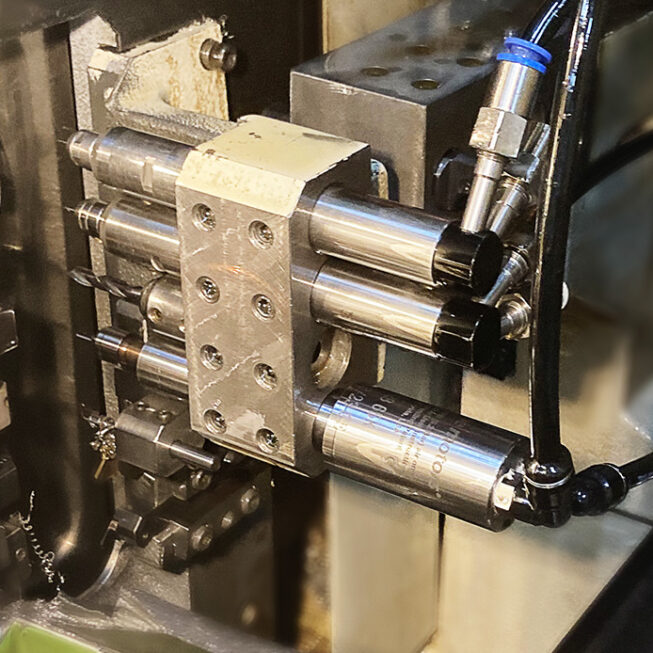

Our direct drives operate with governed high speed with no heat, no thermal effects on accuracy and no duty cycle

This radical innovation in speed and reliability helps medical, electronics, metal working and aviation manufacturers end problems associated with outdated live spindle technology and keep up with production pressure.

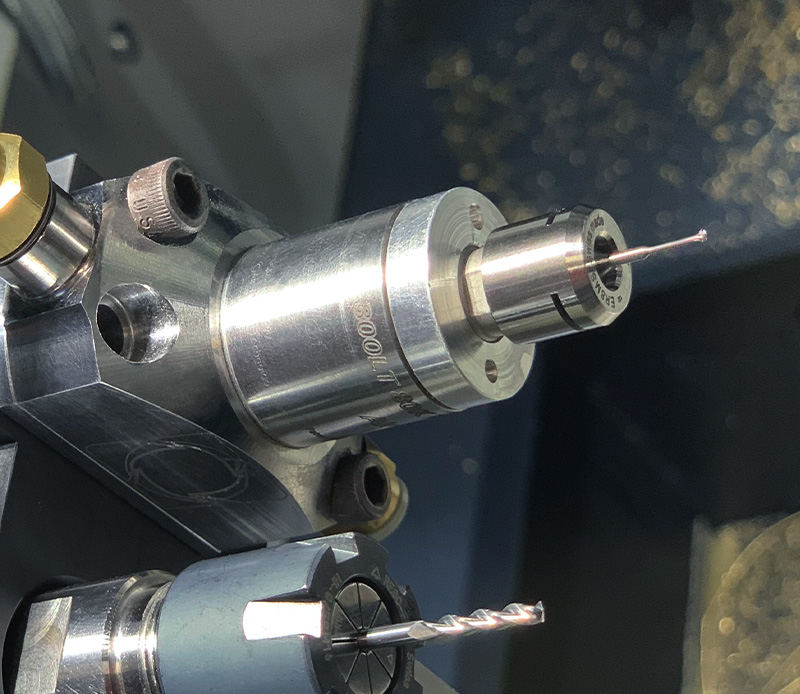

Faster Production with a Finer Finish using High Speed Air Turbine Live Tools®

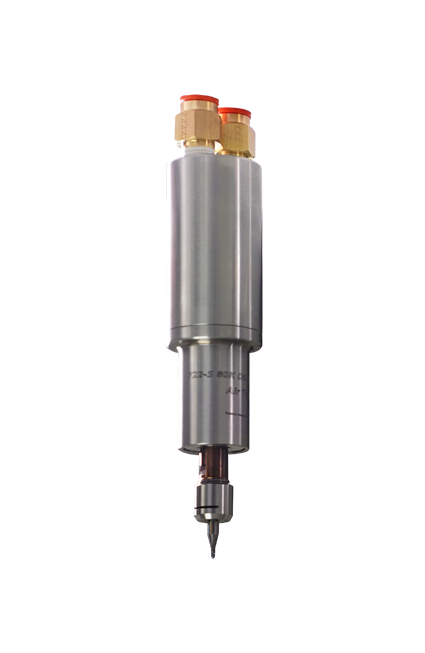

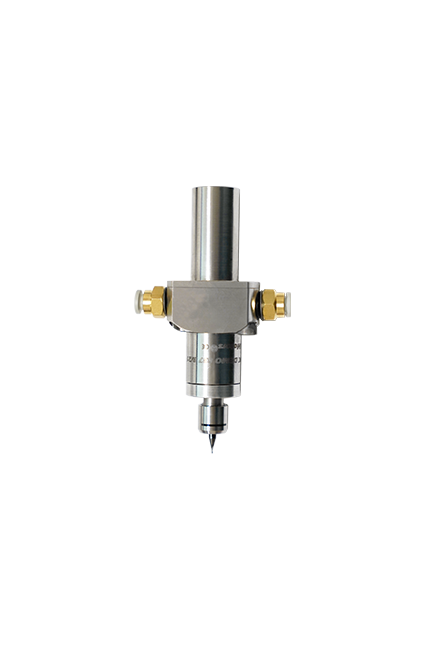

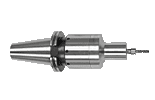

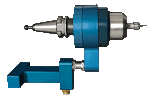

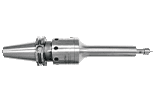

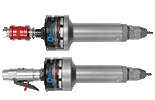

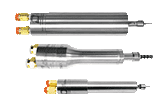

Live Tool Series

See the selection of Live Tools that achieve the real speed in cut and SFM required to optimize your micro tools.

Real High Speed

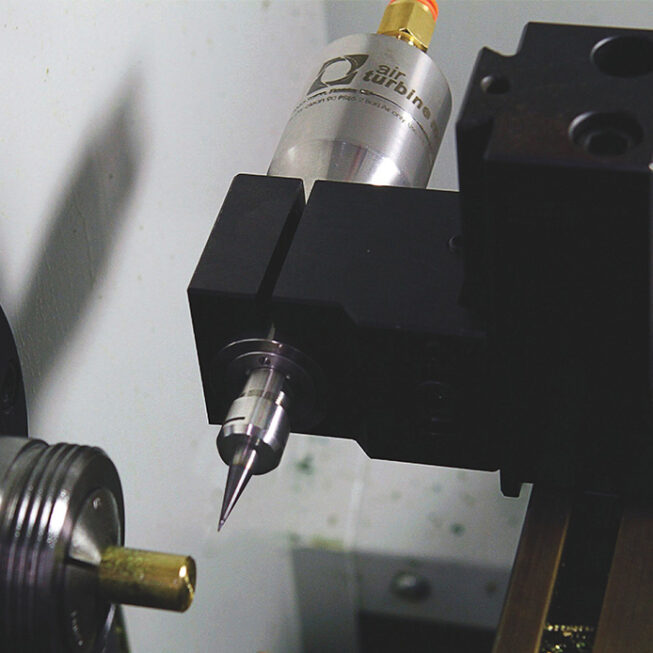

At 80,000 rpm Air Turbine Live Tools® increase feed rates 6 – 10x. Speed up your off-center cuts and exponentially increase the production from your lathes. You can machine titanium and steel – our patented governor increases air flow on demand, keeping you at high speed on the tool path.

Quick and Simple to Install

With just two moving parts Air Turbine Live Tools® operate differently. This mechanism with no heat and low friction gives you durability as well as consistent SFM. Just drop the 800 Series into any boring bar holder and connect 90 PSI / 6/2 dry compressed air (filter included).

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].