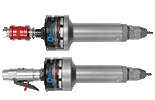

Keep Up with Production Pressure with Air Turbine Live Tools®

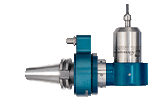

Faster Production with a Finer Finish using High Speed Air Turbine Live Tools®

Achieve the Proper Surface

Footage for Micro Tooling

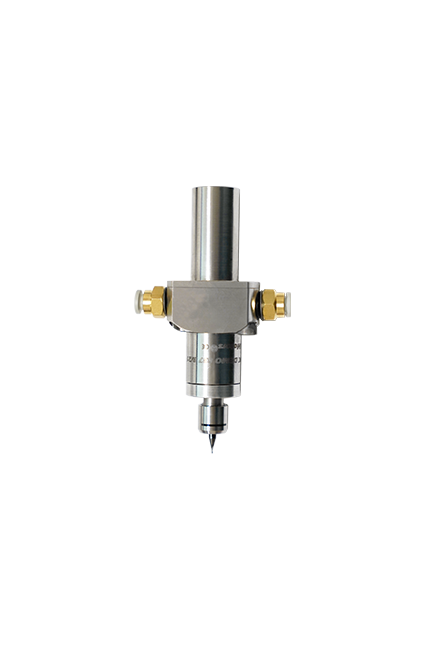

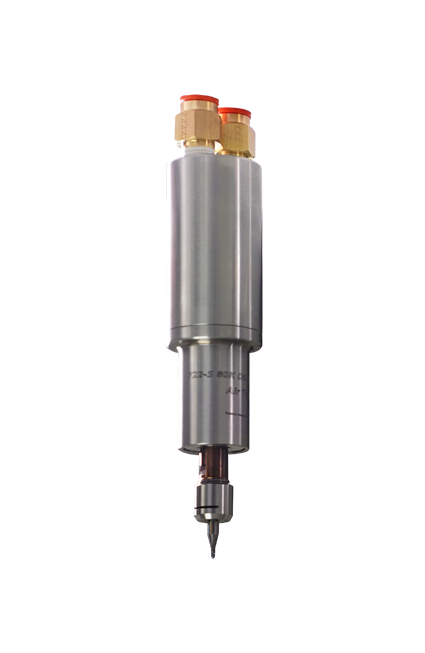

Air Turbine Live Tools® run at high fixed speeds and can operate on any lathe without changing your RPM. Simply change your feed rate to get your desired chip load and get the proper surface footage for micro tooling.

We eliminate the control box, wiring, high frequency brushes and programming complexity. There’s no oil or lubrication, too. Quicker and simpler than traditional live tool spindles.

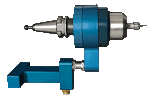

Why are Air Turbine Live Tools® Different?

Direct Drive Reliability

►

Maintain constant high speed and power under load.

►

Only 2 moving parts.

►

No maintenance.

Simple Installation

►

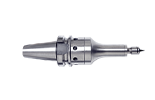

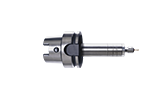

Just drop into your boring bar holder and connect 90 psi/6.2 bar air.

►

No control box.

►

No wiring.

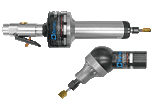

Improved Surface Quality

►

No heat or thermal expansion.

►

2µ precision.

►

Low vibration.

Faster Production

►

No duty cycle.

►

Longer tool life.

Simple Installation

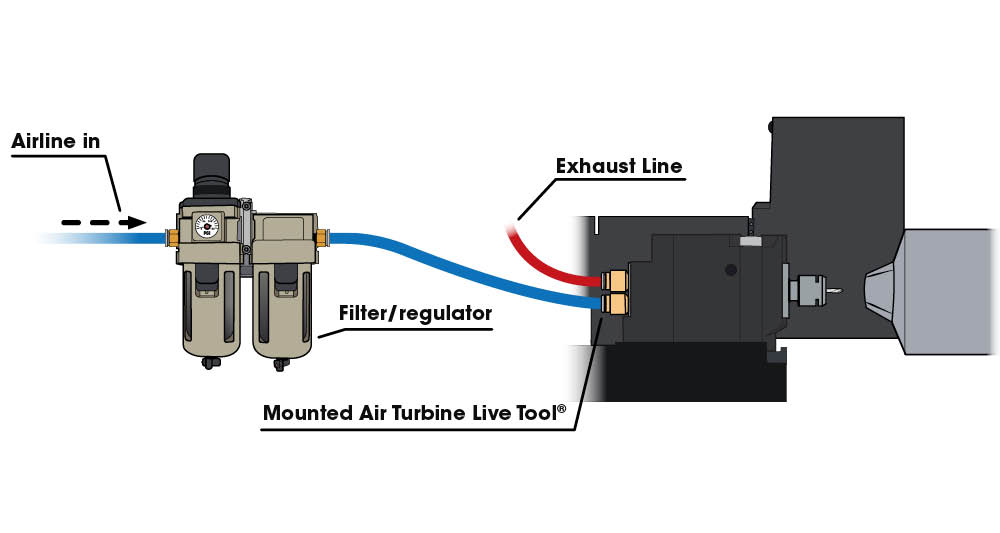

Air Turbine Live Tools® are quicker and simpler than traditional live tool spindles; only requiring 90 psi /6.2 bar dry compressed air to operate. There is no control box, wiring, oil lubrication or program complexity to worry about.

Just mount the tool into your lathe’s boring bar holder and connect the 90 psi/6.2 bar air to the included filter.

Setup diagram showing a 90 psi/6.2 bar air connection from the filter/regulator to the mounted Air Turbine Live Tool®.

Keep up with Production Pressure with 80,000 RPM Air Turbine Live Tools®

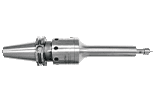

Real High Speed is Not "Nominal RPM"

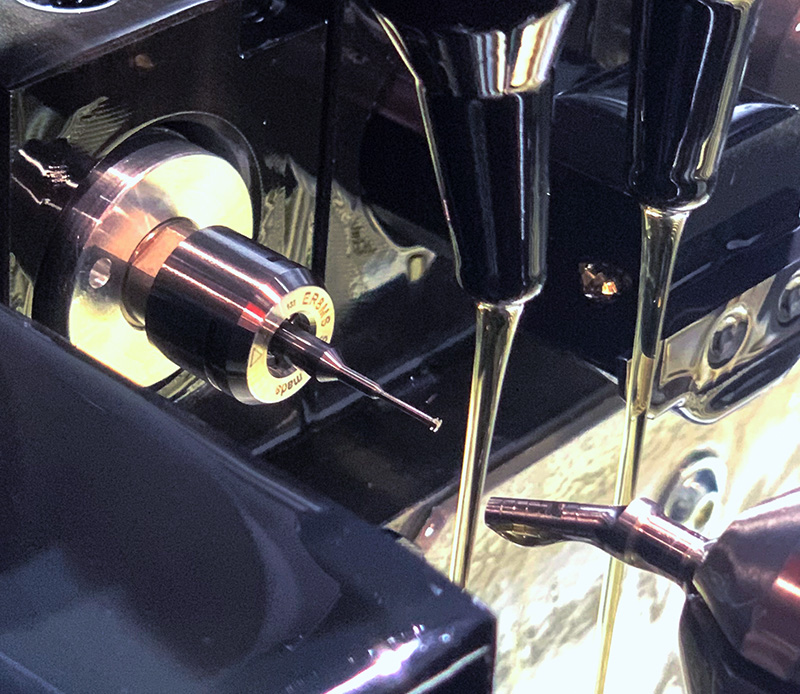

At 80,000 RPM Air Turbine Live Tools® increase feed rates 6 – 10x. Speed up your off-center cuts and exponentially increase the production from your lathes by easily machining titanium or steel.

Our constant high speed in cut will improve your surface finishes and increase tool life while reducing production time.

2 Micron precision delivers the finer finished surfaces with no feed lines. Our technology is very different from nominal high speed spindles that drop immediately on tool engagement.

Find the right Air Turbine Live Tool® for your Application

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].