Our Power Curve Is Inverted!

These Governed Turbines Increase Power as Speed Increases

Maintaining 25,000 to 90,000 RPM in Your Tool Path

When evaluating CNC spindle performance, the relationship between speed and delivered power is crucial. Electric, coolant and geared air spindles lose torque and power as the RPMs rise, causing performance to fade just when high-speed cutting demands the most from your tool. Air Turbine Spindles®, however, deliver a unique solution: our patented, governed air-driven design produces an inverted power curve – More power as speed increases, and an increase in air flow to maintain high speed on your toolpath.

Comparative performance is illustrated on a graph below.

Air Turbine Spindles® 625 Series Speed and Power Ratings

VS Generic HF and Other Air Spindles

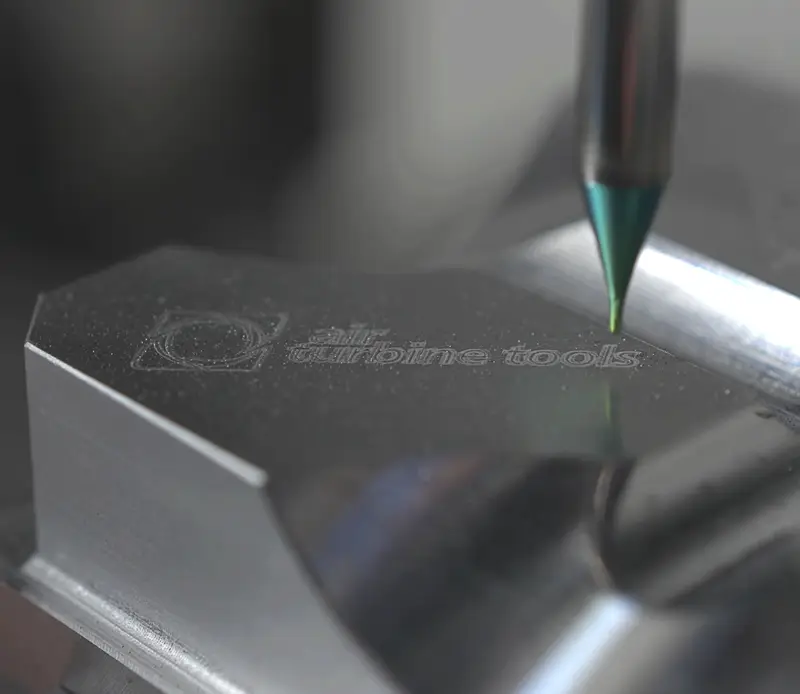

Proof We Maintain Constant 50,000 RPM In The Cut

Why Is This Performance Advantageous?

Having more power at higher speeds delivers real benefits:

►

►

►

►

Increase Production by up to 10 Times on Your CNC Machine

Increase Your Revenue With an Air Powered Motor

What are the Real-World

Gains for CNC Machining?

CNC shops, automation lines, and robotic systems benefit from the inverted power curve by achieving reliable high-speed cutting in demanding sectors such as aerospace, medical device, and electronics manufacturing. This technology also enhances repeatability and improves part quality, even on the smallest geometries.

Additionally, Air Turbine Spindles, Motors, and Live Tools® enable easy, drop-in spindle upgrades that require only a single airline of 90 psi (6.2 bar) air; without the need for complex wiring or lubrication systems.

See the Results, Not Just the Claims

The difference is clear on the power curve: when plotted, Air Turbine Spindles, Motors and Live Tools® curve upward as RPM increases, compared to the downward trend of conventional spindles. This allows shops to operate with confidence that high-speed doesn’t mean low power or fading results, no matter the workload.

Contact Us For A Quote Today!

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].