What Makes a Pencil Grinder So Important in Precision Manufacturing?

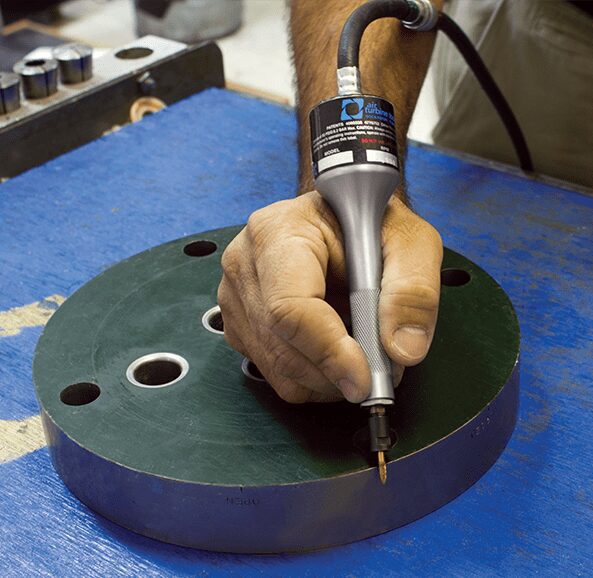

Imagine writing for hours with a pencil that’s heavy, loud and vibrates so much it leaves your hand and wrist aching. Unbearable, right? The same principle applies to poorly designed pencil grinders. These tools are essential in precision manufacturing tasks like deburring, polishing, sanding and grinding. Yet, when workers use subpar pneumatic tools, it can result in hand-arm stress, fatigue and long-term health issues like Carpal Tunnel Syndrome.

Switching to ergonomic, low-vibration air grinders doesn’t just protect workers, it boosts precision, quality and throughput.

These Air Tools Cut Steel and Stress

How Do Low-Vibration Air Grinders Improve Safety and Comfort?

Worker safety is deeply affected by tool vibration levels. Long-term use of high-vibration tools can lead to Hand-Arm Vibration Syndrome (HAVS) and other repetitive stress injuries.

Staying compliant with the Exposure Action Value (EAV) of 2.5 m/s² A(8) and the Exposure Limit Value (ELV) of 5 m/s² A(8) is key to managing risks, as specified by ISO 2631 and Directive 2002/44/EC.

Simply put:

EAV = the point where action must be taken to reduce risk.

ELV = the limit that must never be exceeded.

A(8) = exposure averaged over an 8-hour workday.

Select air pencil grinders have a “Time to Reach EAV” of at least two to three times the standard 8-hour workday. Advanced models can theoretically operate for 24 hours, or even up to 345 hours, without exceeding the EAV threshold. That’s a massive improvement in both safety and tool performance.

By investing in low-vibration pencil grinders, manufacturers can reduce fatigue, improve control and protect workers from injury, all while increasing productivity.

65,000 RPM Pencil Grinder Improves Precision for Finer Surface Quality

Are Air Tools Better Than Electric or Vane Tools?

Yes—and here’s why:

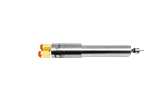

Air Turbine Tools® grinders and routers, in contrast, offer:

Quiet operation (as low as 67 dBA).

Zero lubrication requirements.

Lightweight, compact designs.

Cool-running even under high load.

What Are the Advantages of Ergonomic Pneumatic Grinders?

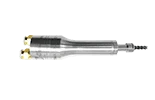

No heat, no maintenance, no lubrication, no oil misting with 50,000 RPM on this Pencil Grinder

Lightweight Design

Models as light as 6 oz (0.17 kg) allow for a relaxed grip and precise, fatigue-free control, even during long shifts.

Cool Operation

Air Turbine Tools® stay cool to the touch, eliminating the need for gloves or downtime due to overheating.

Quiet Performance

Air Turbine Tools® pencil grinders operate below 67 dBA, enhancing focus and reducing workplace noise hazards.

How Do High-Speed, High-Torque Grinders Improve Cut Quality?

With up to 90,000 RPM and power levels reaching 1.4 HP, Air Turbine Tools® increase airflow to match cutting load. Their patented governor technology ensures consistent torque and speed, even when cutting corners or working with hard materials.

Operators don’t have to apply extra pressure, reducing fatigue and improving cut quality. The result: smooth, precise finishes without distortion or rework.

Why Does Lubrication-Free Operation Matter in Clean Environments?

Traditional air tools often require lubrication, which releases oil mist into the air, contaminates sensitive workpieces, and adds maintenance and cleanup time.

Air Turbine Tools® operate 100% oil-free, making them ideal for clean environments such as:

►

►

►

Why Should Manufacturers Prioritize Ergonomic Tools?

Comfortable, high-performance tools don’t just protect employees, they help keep them engaged and on the job. By reducing fatigue and injury risk, ergonomic air tools help manufacturers improve retention, boost output and consistently achieve high-quality results.

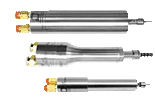

Cut Cleaner at 65,000 RPM with No Maintenance and No Stress

Explore Air Turbine Tools® Full Range of Ergonomic Solutions

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].