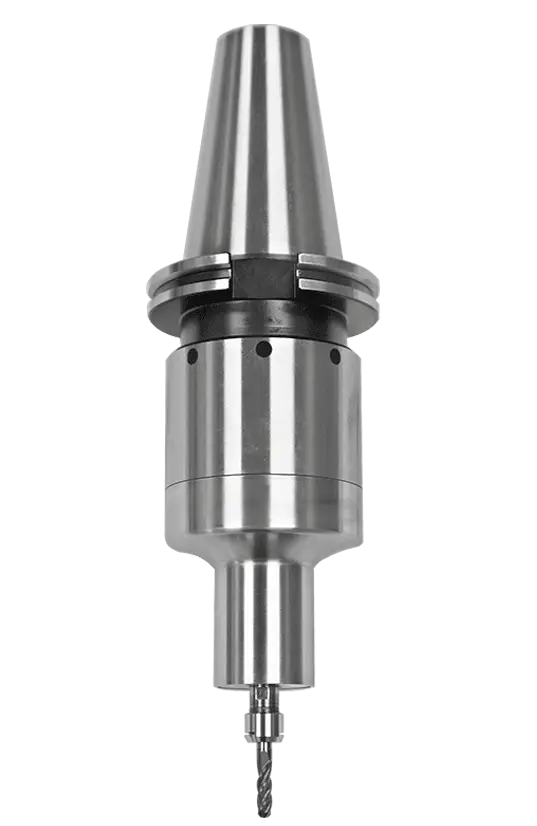

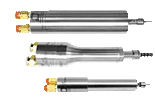

Air Turbine Tools® 40,000 RPM Spindle

Improves Cycle Time and Surface Finish

Air Turbine Tools® offers the 0.88 HP governed 40,000 RPM 650 CNC spindle series, designed to dramatically accelerate machining rates.

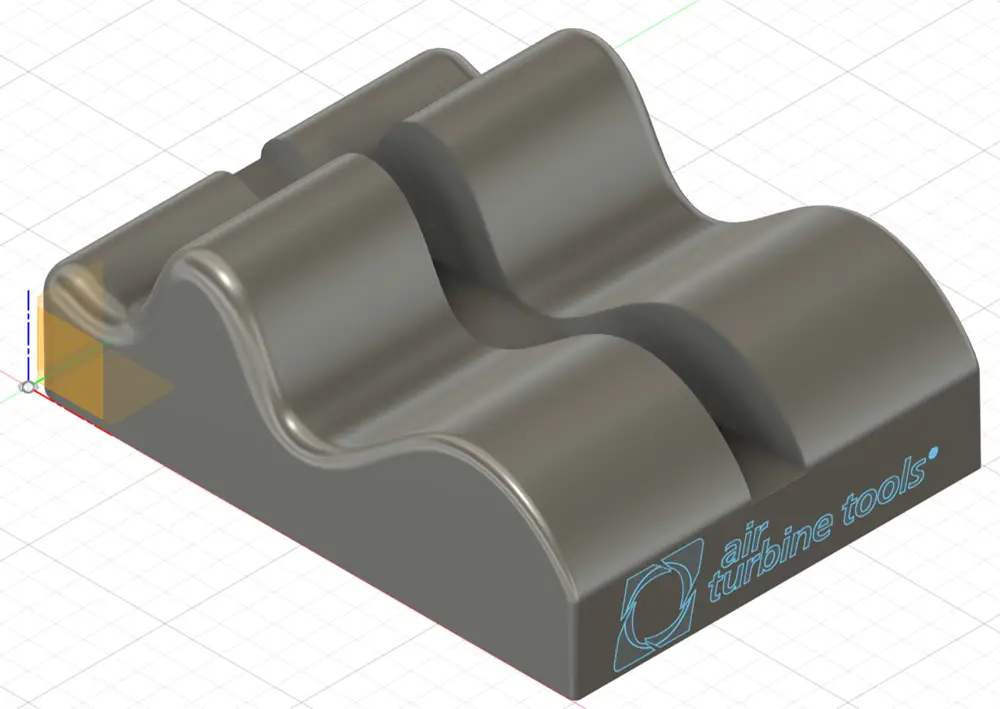

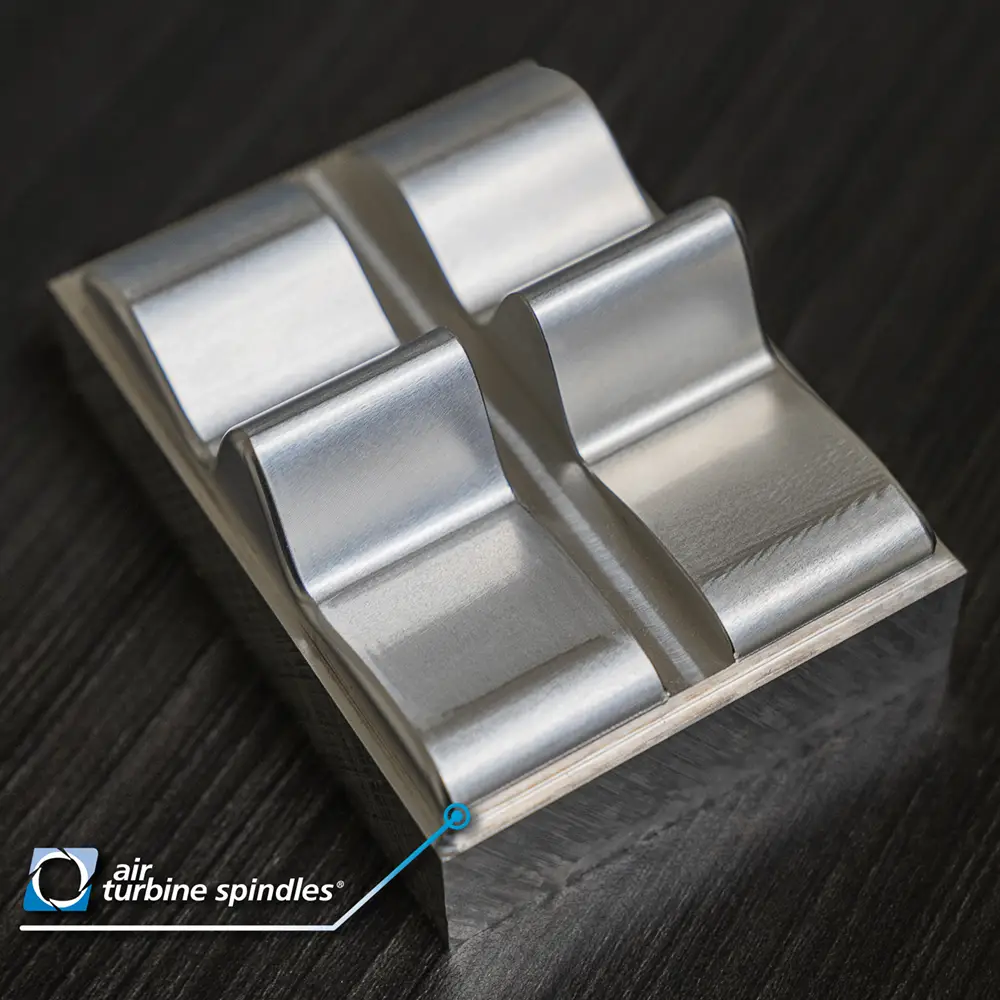

In a recent side-by-side study, AW2024/31355 aluminum was milled using both a standard Haas 8,000 RPM CNC spindle and the Air Turbine Tools® 650 spindle series, each with a ball nose tool.

This 40,000 RPM CNC Spindle Cuts Your C/T Drastically

What Challenges Do Conventional CNC

Spindles Face When Milling Aluminum Alloys?

Machining aluminum alloys such as AW2024/31355 with standard CNC spindles can be both time-consuming and costly. For example, a typical 8,000 RPM spindle, commonly found in many Haas CNC machines, may take up to two hours to machine a contoured part with a ball nose tool. These extended cycle times not only reduce throughput but can also compromise surface finish quality and drive up overall production costs.

What Makes Air Turbine Tools® Spindles

Ideal for High-Speed Machining?

Engineered for both speed and power, Air Turbine Tools® spindles deliver up to 1.4 HP while running at rotational speeds from 25,000 to 90,000 RPM. Installation is simple; just connect to 90 psi (6.2 bar) compressed air, and the high-speed spindle is ready to run. The patented governor ensures consistent airflow and maintains precise speeds, making these spindles fully compatible with automatic tool changers (ATC) on any CNC machine.

With only two moving parts, Air Turbine Spindles® run cool with no heat build-up and require minimal maintenance. Their design enables continuous 24/7 operation with no duty cycle limitations, consistently achieving micron-level accuracy of 2 microns throughout production.

Optimize machining processes with faster cycle times and superior surface quality using Air Turbine Tools® spindles.

Learn More About Air Turbine Spindles® and Contact Us for a Demo

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].