Dramatic Insert

Reducing Costs and Eliminating Repair Time for Innovation Industries Inc

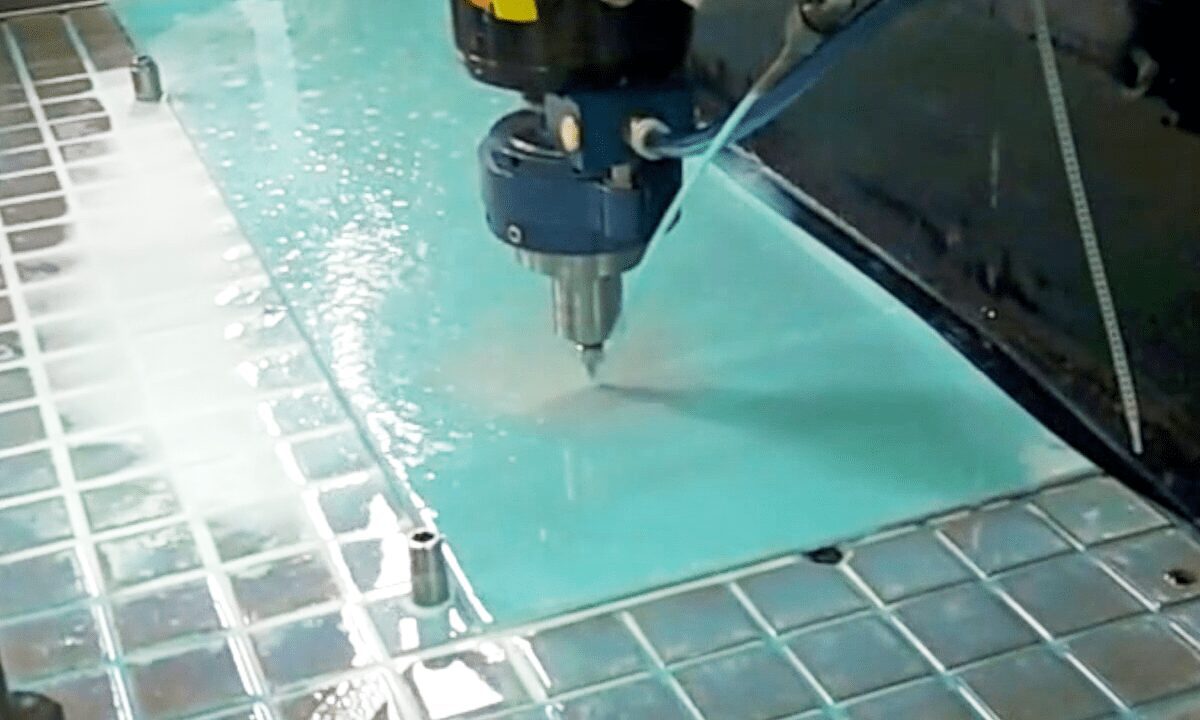

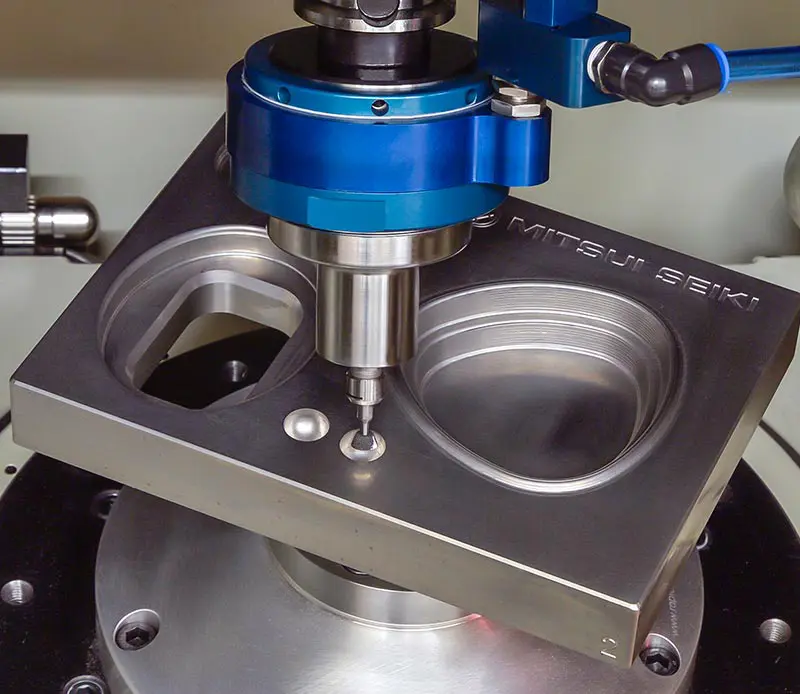

At Innovation Industries Inc, Arkansas Mr. Doug Holt was using speeders on a Haas Router with max speeds of 25,000 RPM. Innovation is engraving 316L stainless steel at a 0.016” (0.4064 mm) D.O.C and 14 IPM (355 mmpm) on each pass.

Innovation’s geared “speeder” was burning through inserts very rapidly. In fact, it would take 3 – 4 inserts just to finish one 45 min engraving sequence. Mr. Holt’s “speeders” would break down frequently.

Air Turbine’s Task:

Match the cycle time, be more cost-effective, and save tool life.

The Result:

At the end of a test, Mr. Doug Holt saw Air Turbines governed 40,000 RPM 650CAT match the same D.O.C and feed rates of the speeder, but there was a big difference. While the speeder took 3 – 4 inserts to finish one engraving sequence, Air Turbine Spindles® 650 was able to use the same insert for 4 sequences in a row.

Innovation Industries, Inc. purchased four 650 spindles immediately.

The Cost Comparison:

Each “speeder” costs approx. $20,000 and each repair $5,000. Innovation Industries, inc. was spending in excess of $80,000+ p.a. just on speeder repairs.

A new 650CAT40, US list price is less expensive, brand new, than the repair of a single speeder.

“Air Turbine’s saves us thousands of dollars every year in faster cycle times, new spindle purchases, repair costs and insert tooling costs. My Air Turbine Spindles® extend insert life 4X engraving, and they are very reliable”

– Mr. Holt

CNC Spindle Engraving Stainless Steel at 14”/min

Cut Cycle Times by 6-10x

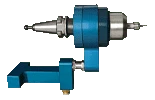

Air Turbine Spindles are air-powered and air-cooled, making them have no heat, no duty cycle, and great durability. The governor control delivers power on demand with speeds that do not fade in cut. Load automatically from the magazine into the router turret using Air Turbine Technology Inc’s patented wrap-around Tool Changer Mounting Assembly – or TMA.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].