Keep Up With Production Pressure

High-precision medical, aerospace and microelectronics manufacturers rely on Swiss-type lathes to produce small, intricate parts with tight tolerances. However, the efficiency of these machines depends heavily on the tooling used.

Air Turbine Technology’s miniature live tooling is revolutionizing the productivity of Swiss sliding headstock lathes by increasing spindle speed, dramatically reducing cycle times and enhancing surface finishes—all while extending tool life.

What Are Air Turbine Live Tools® for Swiss Lathes?

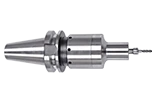

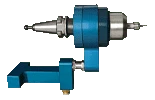

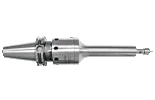

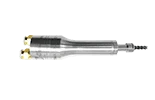

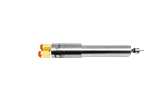

Air Turbine Live Tools® governed 65,000 and 80,000 RPM spindles drop into existing tool holding on Swiss-type CNC lathes to accelerate milling, micro-drilling and finishing operations.

Unlike traditional live tooling, which often struggles with torque loss and speed limitations, Air Turbine Live Tools® operate at fixed high RPM’s whilst generating no heat, delivering consistent precision at 2µ and 5– 10 X higher productivity on small-diameter parts.

Make Stainless Steel Fly At 80,000 RPM On Your Lathe

Why Are Air Turbine Live Tools® Essential for Swiss Machining?

If you’re struggling with heat buildup, tool wear, or poor surface finish, upgrading to Air Turbine Live Tools® solves all three. These tools maintain high RPMs without electronics, control boxes or lubrication. Reliable high speed in Swiss-type lathes is the best way to enhance tool life in micro-machining. These tools eliminate common issues, like thermal expansion, excessive wear on the tool and insufficient cutting SFM for small tooling—problems that often plague conventional live tooling.

Faster Production with a Finer Finish using High Speed Air Turbine Live Tools®

At speeds from 40,000 to 80,000 RPM, Air Turbine Live Tools® significantly reduce cycle times, allowing manufacturers to produce more parts per shift. Their precision and stability eliminate secondary finishing processes, improve part quality while reducing operational costs.

A Revolution in Simplicity - No Control Box, Wiring or Lubrication

Requiring just a connection to dry clean 90 psi / 6.2 bar air, these spindles eliminate the expensive control box, wiring and lubrication used in traditional live tooling. Air Turbine Live Tools® eliminate contamination, making them ideal for medical and aerospace component production.

Instead of changing spindle speed with complex re-programming on a control box, the operator merely needs to change the rate of advance of these governed fixed speed spindles to achieve the desired Surface Feet Per Minute required for any small cutting tool.

What Are the Benefits of Air Turbine Live Tools® for Swiss lathes?

One of the biggest advantages of using governed Air Turbine Live Tools® is the maintenance of high speed in cut without compromising accuracy. By maintaining consistent high speeds, these tools prevent tool deflection, reducing scrap rates and ensuring repeatability in micro-machining applications.

Manufacturers working with stainless steel, titanium, inconel and aluminum, as well as composites will see immediate benefits from using Air Turbine Live Tools®. These materials require high cutting speeds to achieve optimal tool performance and life.

Whether machining screws, medical implants, aerospace fasteners or precision electronic components, Air Turbine Live Tools® have proven they enhance the capabilities of Swiss-type machines, allowing for complex geometries and ultra-fine detail work with micro tools.

Keep up with Production Pressure with 80,000 RPM Air Turbine Live Tools®

Top Benefits for Swiss CNC Applications

►

►

►

►

►

►

►

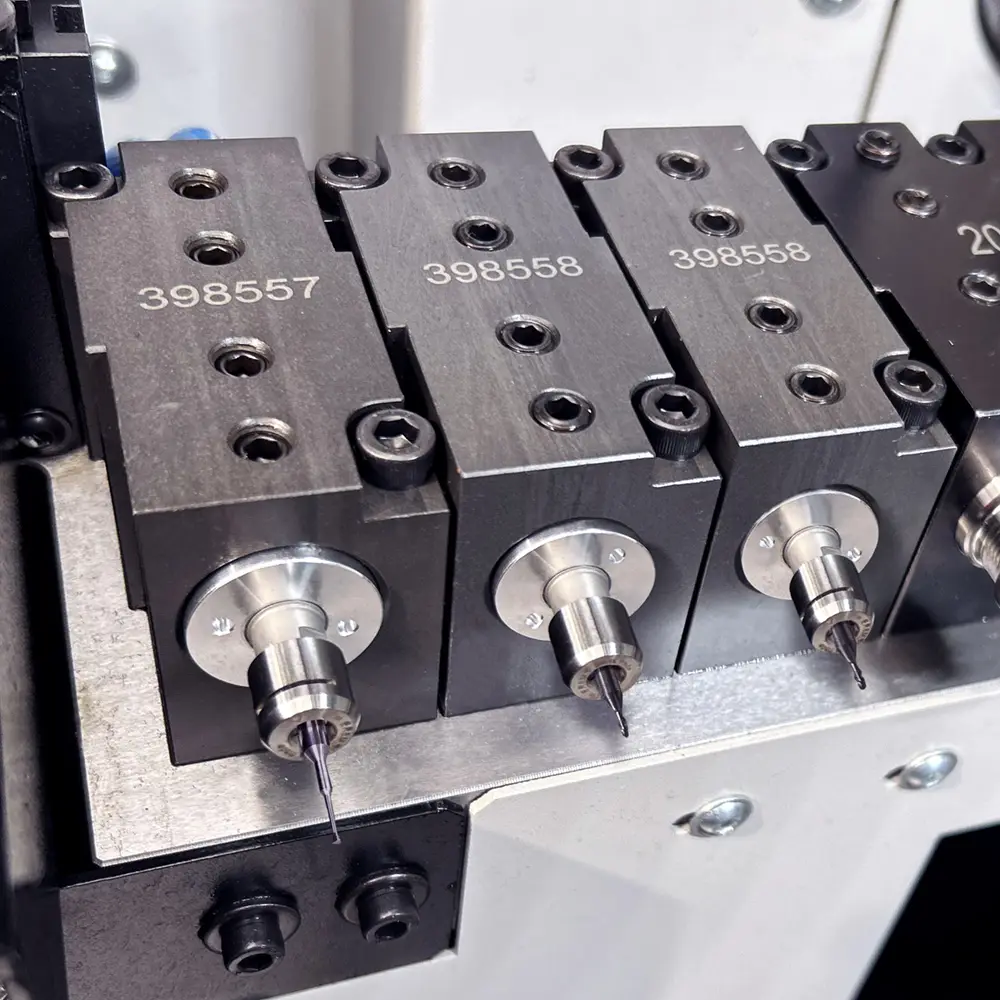

Simple Integration, Powerful Results

Air Turbine Live Tools® drop right into your existing Swiss machine tool holders—no reprogramming required. Just adjust your feed rate to achieve the required SFM for any small-diameter tool.

Ready to Upgrade Your Swiss Machine?

If you’re looking to optimize your Swiss machining process, improve part quality and boost productivity on your Swiss machines, investing in high-speed Air Turbine Live Tools® could be the solution. These tools are easy to install, reducing cycle times, minimizing tool wear and eliminating costly secondary operations, and therefore provide an immediate competitive advantage.

Service & Support

Support is always available from our technical team in the USA and Germany. Repair Service is available in Florida and Munich. Call our factory technicians at +1-561-994-0500 or email us at [email protected].