650LJS 100mm

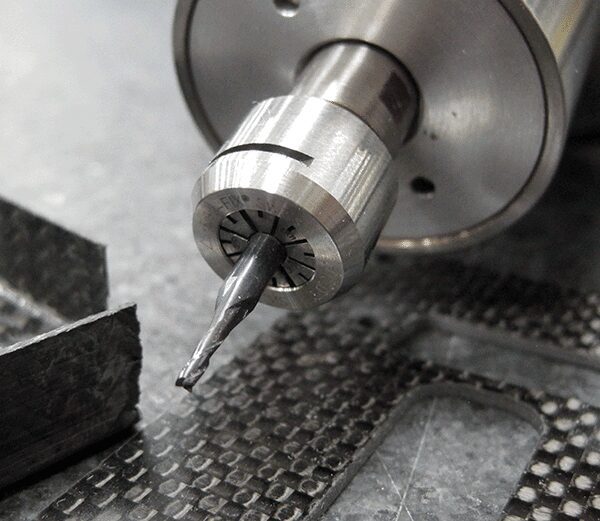

650 Extended Barrel CNC Spindle Series

100mm

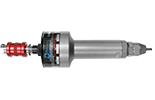

The robust, long body 650LJS (100mm) (3/4” / 20mm Straight Shank) delivers governed constant high speed and power under load – 25,000 to 40,000 rpm, < 0.88 hp (0.66 kW) with double front ceramic bearings. The 650L (100mm) Series is ideal for heavier duty applications and milling hard materials in corners in deep pockets. The governor-controlled turbine maintains rated high speed, optimizing tool performance and life. Effective in all materials, including tool steel, titanium, and ceramic. Ultra-low vibration and no heat in 24/7 operation. Selectable rear or side air feed on each spindle. Automatic Loading from the magazine on all machines.

| 650LJS (100mm) Specifications | |||

| Speed RPM | 25,000 | 30,000 | 40,000 |

| Power Rating hp (Kw) | 0.80 (0.60) | 0.83 (0.62) | 0.88 (0.66) |

| Inlet Air Pressure | 90 psi (6.2 bar) | ||

| Air Consumption Idle cfm (l/s) | 13 (6.1) | 14 (6.6) | 14 (6.6) |

| Air Consumption Working Flow (l/s) | 14 (6.60) - 35 (16.5) | ||

| Sound Level | Less Than 78 dBA | ||

| Max Shank Capacity | ER 11 - 1/4” (6mm) | ||

| Spindle Weight | 94.4 oz (2.67 kg) | ||

Reach into deep pockets with 1.4 HP with the Air Turbine Extended Barrel CNC Spindle Series

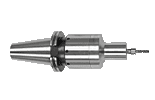

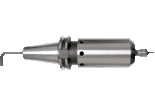

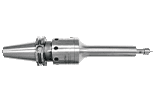

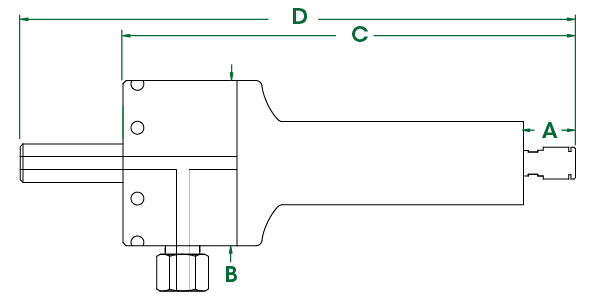

650LJS 100mm Dimensions

| A | 0.99” (25mm) |

| B | 1.62” (41mm) |

| C | 3.23” (82mm) |

| D | 5.59” (142mm) |

| E | 8.22” (209mm) |

| F | 10.24” (260mm) |

Equipment

Included Equipment

Standard Equipment

ER 11 collet system (1/4” or 6mm collet standard – other sizes optional). 3/4” or 20mm shank standard (Metric Shank comes with metric collet, Inch Shank with inch collet). Oil free 90 psi / 6.2 bar, clean, dry air supply required.

| Accessories Models | Part # |

|---|---|

| High Flow Filter / Regulator / Extractor | 30008 |

| Tube 12mm O.D. - 8mm I.D. (order by foot) | 16509 |

| Hose & Fitting - 12mm O.D. - 8mm I.D. - 12’ | 30045 |

We retrofit any CNC machine to mill at a constant high speed 24/7 – so any CNC can be a high-speed machine. This includes, but isn’t limited to DMG MORI, Haas, Fanuc Robodrill, Doosan, Hermle, Hurco, GROB, Brother Okuma, Makino and Mazak. Easy installation using selectable air feed inlets – choose side inlet NPT / Stop Block or center through shank/tool holder air feed. HSK, CAT, BT, and DIN Toolholder options are available. Learn more about Air Turbine Spindles on your CNC Machine by visiting their page at the links below.

| ER11- 1/4" | ER11- 6mm | ||

|---|---|---|---|

| Speed RPM | Part # | Speed RPM | Part # |

| 25,000 | 64900 | 25,000 | 64901 |

| 30,000 | 64902 | 30,000 | 64903 |

| 40,000 | 64904 | 40,000 | 64905 |